The bigger picture

Heterogeneous catalysis is a key enabling technology for the transition from a fossil-based society to a renewables-based scenario. For example, CO2, the primary driver of climate change via the greenhouse effect, is also a sustainable carbon resource for the production of value-added chemicals. Zeolites, a type of aluminosilicates, are foreseen to play a pivotal role in the production fuels and chemicals from captured CO2 in a circular economy. About 1 million metric tons of zeolite catalyst are already consumed by the refinery and petrochemical industries every year. The overarching objective of TomoCAT is to provide insights that might pave the way for a more efficient utilization of these catalyst materials. This has two benefits. First, less material will be consumed every year, leading to obvious savings. Second, a more efficient utilization translates to smaller chemical reactors and less process downtime, leading to improved technology and further savings.

What we do

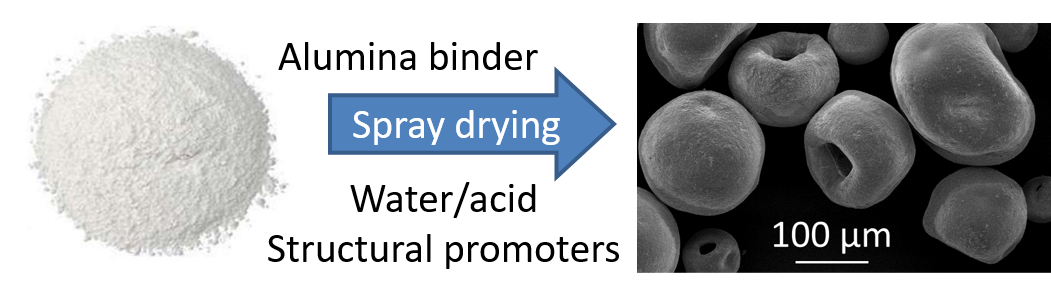

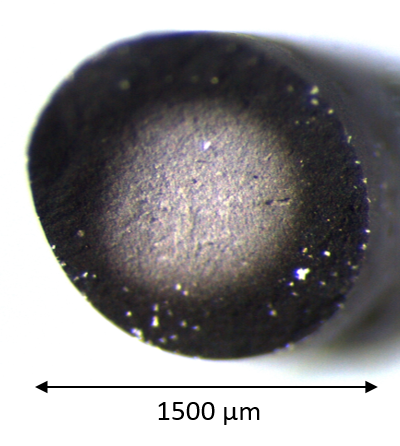

Industrial catalysts are always shaped into millimeter-sized catalyst objects suitable for large scale industrial use. The key objective of TomoCAT is to achieve a description of how various chemical phenomena occur in these shaped objects, resolved both in time and space. Time in this context means the time of use in an industrial process, whereas space means spatial resolution across shaped catalyst objects. This requires utilization of national and international research infrastructures and very advanced X-ray methods for 4D imaging and tomography.

In particular, we are interested in methanol-to-hydrocarbon processes. These chemical reactions occur inside the nanopores of zeolite materials. Here, we investigate how "coke" (unspecific, higher-order hydrocarbons that block the nanopores and hence deactivates the catalysator) forms during the reaction. On the other hand, the coke can be removed again by heating the deactivated catalysator up to several 100°C, where the coke simply combusts. To understand these processes, we combine basic sample characterization (differential scanning calorimetry, thermogravimetric analysis, surface measurements) with advanced X-ray techniques (diffraction, tomography).

Related Publications:

- Rojo Gama et al., A Straightforward Descriptor for the Deactivation of Zeolite Catalyst H-ZSM-5. ACS Catalysis, 2017. 7(12): p. 8235-8246. DOI: 10.1021/acscatal.7b02193

- Rojo Gama et al., Deactivation of Zeolite Catalyst H-ZSM-5 during Conversion of Methanol to Gasoline: Operando Time- and Space-Resolved X-ray Diffraction. The Journal of Physical Chemistry Letters, 2018. 9(6): p. 1324-1328. DOI: 10.1021/acs.jpclett.8b00094

Funding: Norwegian Research Council, Program Nano2021