Operando approach

Mechanistic understanding of chemical reactions on catalytic active surfaces is most often extracted from experiments performed under ultra-high vacuum (UHV) conditions. This creates a pressure gap between the conditions the real catalyst is working at, and the conditions the fundamental studies are performed under. The main cause for this pressure gap is that the normally applied high vacuum surface sensitive techniques (LEED, AES, XPS, LEIS, SIMS) can hardly be combined with the environment to which a catalyst would normally be exposed. A new trend is now emerging; surface sensitive techniques adapted to more realistic reaction conditions. Three well-known examples are Transmission Electron Microscopy (TEM), Scanning Tunnelling Microscopy (STM) and Near-Ambient Pressure X-ray Photoelectron Spectroscopy (NAP-XPS).

Therefore, to get atomistic insight in the active catalytic surface the STM needs to be operated at industrially (diesel engines, chemical factories) relevant conditions (high temperature and high pressure).

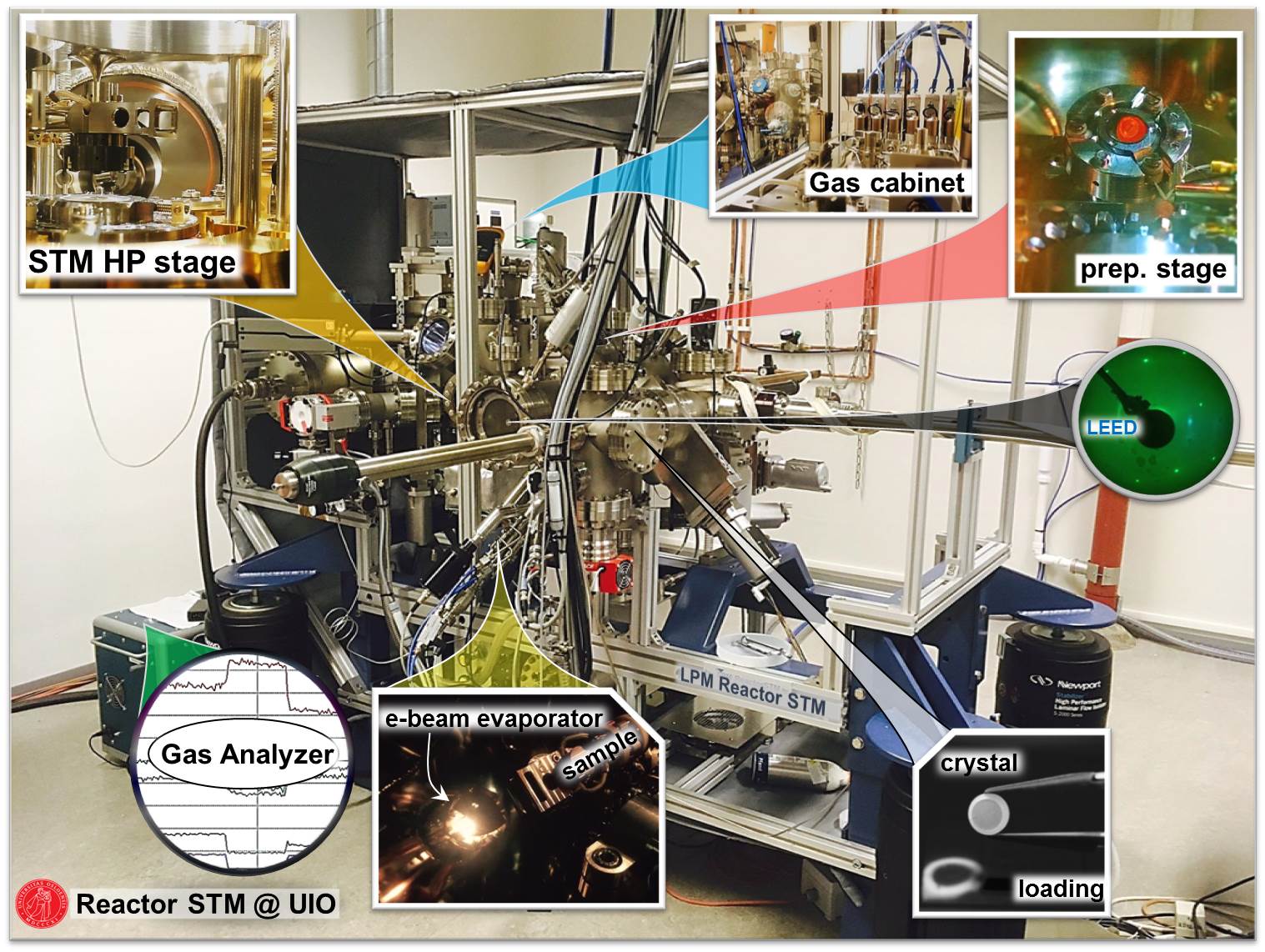

High-Pressure STM at UiO

The reactor STM is an STM instrument (one of 5 world-wide), capable of measuring surfaces at atomic resolution at a video rate speed and at industrially employed conditions of 1-5 bar gas pressure and up to 600 K temperature.

Currently there are two projects running on the Reactor STM: the study of Ammonia Slip 2D model CATalysts (Ammonia Slip Catalysts (ASCAT) - Operando STM), and the NOx abatement project.

Contact

Related projects

- ASCAT - Operando STM

- Bimetallic Co-Re for FT synthesis

- NOx abatement